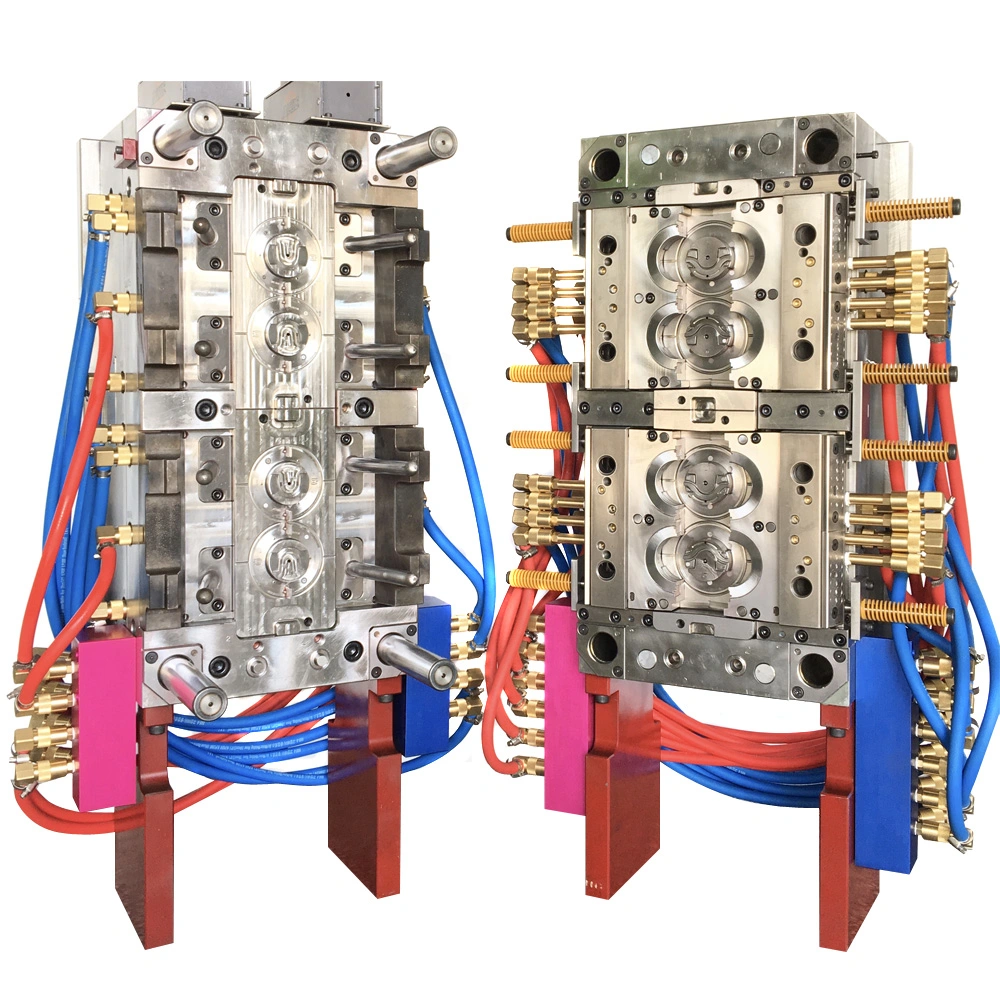

Plastic Injection Moulding Handle for Medical Devices Gas Assist Mold Gas-Assisted Injection Molding Handle PSU Plastic Medical Handle Plastic Parts Mould Maker

Basic Info

| Model NO. | HKM202302031 |

| Warranty | 2years |

| Shaping Mode | Injection Mould |

| Surface Finish Process | Polishing |

| Mould Cavity | Multi Cavity |

| Plastic Material | Peek |

| Process Combination Type | Customized |

| Application | Customized |

| Runner | Hot Runner |

| Design Software | 3D&2D |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | All Time |

| Mould | Plastic Mould |

| Plastic | Plastic Product |

| Mold | Plastic Mold |

| Tooling | Toolings |

| Plastic Injection Mold | Injection Mold |

| Plastic Products | Plastic Parts |

| Medical | Injection Medical Handle Mold |

| Transport Package | Wood Case |

| Specification | Customize |

| Trademark | HKM |

| Origin | Guangdong Dongguan |

| Production Capacity | 500 Sets of Moulds Per Year |

Packaging & Delivery

Package size per unit product 10.00cm * 5.00cm * 1.00cm Gross weight per unit product 0.500kgProduct Description

Product Description

| Product Name | Plastic Injection Moulding Handle for Medical Devices Gas Assist Mold Gas-Assisted Injection Molding Handle PSU Plastic Medical Handle Plastic Parts Mould Maker |

| Material | ABS,PP,PC,PEEK,PEI,TPE,ABS+TPE or any other material as you need |

| Type of enterprise | Professional manufacturer of injection molds and plastic parts |

| Service | Design based on your idea or Make mold and produce based on your drawing |

| Design software | 3D&2D |

| Drawing format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

| Size | As Customer's Requst |

| Product weight | 100kg-20000kg |

| Production ability | Export about 400 to 500 sets of moulds per year. |

| Lead time | 1-5 weeks |

| Assembly & Test | Professional assembly and testing factory |

| Package | Wood case, standard carton, pallet or customized |

| Payment details | T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc |

| Shipping way | By Courier DHL, Fedex, TNT, UPS, EMS, By Sea, By Air |

| Features & Advantage | 1.Professional design team |

| 2.Professional moldflow analysis | |

| 3.Professional mold making team | |

| 4.Professional mold and product QC and technical team | |

| 5.Rich mould making experience for different country clients | |

| Standard | ISO9001:2015, SGS,TUV |

| Application | Auto Parts,Airplane Parts,Household Parts,BMC mold,Appliance Mold,Powertool,Communication parts,Overmold,Insertmold,Unscrewing Mold,Caps,Pipe fitting parts,PVC parts,Micro Precision Mold,High Performance Material mold,Infrared Thermometer,Other Molds. |

Hongke was established in 2008,as an excellent Chinese manufacturer specializes in mould making and injection molding. We are involved in the field of auto parts, household appliances, medical equipment, air plane parts, power tools, BMC parts and etc. We have a strong team of skilled and experienced mould design engineers, NC design engineers, and mould making masters. We are good at complicated mould, precision mould, and large mould making. And we also have rich experience in over mould, double injection mould, unscrewing mould, and high performance material mould.

Project management

We believe that the mould design is the source of the quality. Our mould design concept which we have been insisting is convenient manufacturing and molding.

Before mould design, a detail DFM report and mold flow analysis is important to helped customers improve the product design.

Full 3D mould design, and strict expert review, make the structure and processing more reasonable ,and avoid errors.

Timely analyze and summarize mould testing problems, then improve it. Ensure customer satisfaction of samples exterior and dimensions.

Manufacturing capacity

Adhering to spirit of the craftsman, we are scrupulous with every step of the processing.

Good team cooperation spirit, and fine division of labor, maximum performance of the team.

We regard the quality as the life of our company, in order to ensure the excellent quality of the mould, we strictly control the quality, to make customers reassured.

We constantly perform well in manufacturing capability and accuracy. We would like to establish a seamless service with the customers. Rapid response, timely communication and perfect execution make customer satisfaction.

Certifications

Our Services