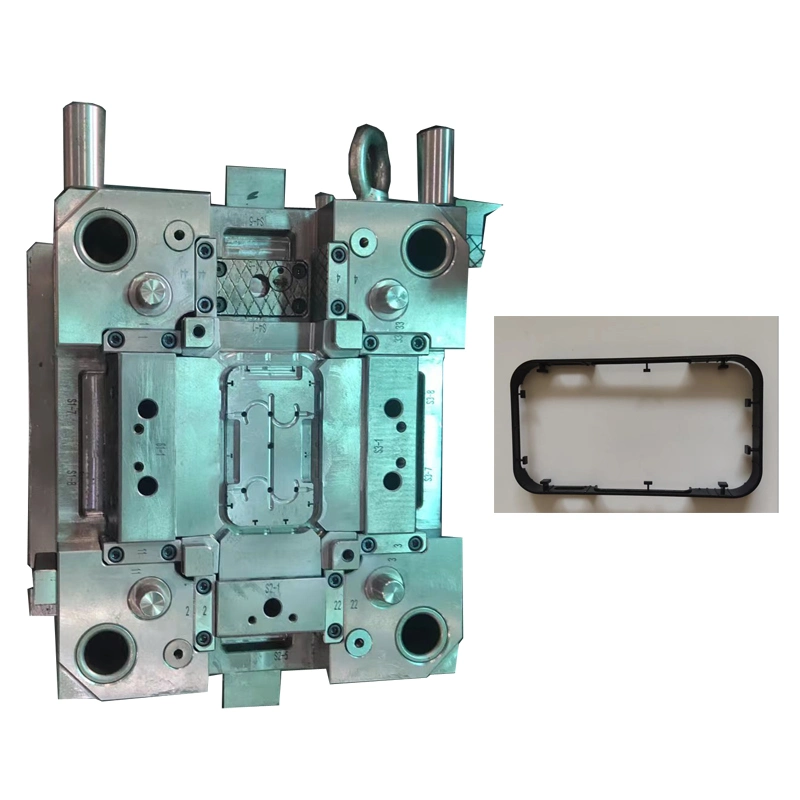

High Precision 300000-500000 Shots Plastic Injection Mold for Plastic Parts Outline Border

Basic Info

| Model NO. | HW-223 |

| After-sales Service | Any Question Please Feel Free to Contact Us. |

| Warranty | Any Question Please Feel Free to Contact Us. |

| Mould Process Machine | CNC, EDM, Grinding, Wire-EDM, Milling, etc |

| Mould Runner | Cold/Hot Runner - Point Way, Side Way, Follow Way |

| Mould Design Software | Ug, Proe, CAD, Caxa etc. |

| Mould Surface Treatment | Mirror, High Polishing |

| Mould Life | 300K-500K Shots, Depend on Mold Steel |

| Mould Steel | S50c/P20h/718/H13/S136/2316/2738etc |

| Transport Package | Box |

| Specification | Custom |

| Trademark | HOWE or Custom |

| Origin | China |

| HS Code | 3901100001 |

| Production Capacity | 10000PCS/Week |

Packaging & Delivery

Package size per unit product 40.00cm * 30.00cm * 20.00cm Gross weight per unit product 20.000kgProduct Description

Product Description

| Product name | Multi cavity hot runner injection mould supplier |

| Mould Material | P20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9,SKH-51,M35,M42,ASP23 |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Base material | P20, 2738, 2344, 718, S136, 8407, NAK80, SKD61, H13 |

| Product Material | ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF |

| Main Technology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

| Equipment | CNC, EDM, Cutting off Machine, plastic machinery, plastic part, etc |

| Mould Cavity | One cavity, multi-cavity or same different products be made together |

| Runner System | Hot runner and cold runner |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Mould Life | 300-500K shots |

| Mould Precision | +/-0.05mm--+/-0.1mm |

| Producing Process | Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending |

Other Products

Plastic Mold (Moulds) production process1. 3d Design/Samples for quotation: According to 3D drawing or samples for quotation.2. Negotiations: Including the price of moulds, moulds sizes, material for cores & cavities, the weight of the product, part cost, payment, moulds lifetime, delivery, etc.3. Purchasing Order: After the customer confirming the mould design and quotation.4. Making mold: Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production.5. Production schedule: Every week we will feedback to the customer mold progress(picture).6. sample shoot: We provide the moulds test samples for confirmation(about 10-15 pieces), then, get your signature sample, mass production.7. Package: Wooden case for moulds, cartons for parts, or as your requirements.8. Delivery: deliver goods by air or by sea.

Quality ControlHowe Mould Quality Control1.Mould Material Q/Ca) mould steel checking (hardness,flaw detection)b) mould spare parts checking (hardness,size)2.Mould Making Process Q/Ca) design checking ( part design,mould design,mould engineering drawing)b) mould size checking (according to drawing)c) mould testing (check mould working,sample)

Company Profile

Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination is incorporated into the actual product! If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!Our products include :1. Custom Plastic Injection Parts2. Multi-cavity plastic parts3. High Precision Molds4. Insert & over molding5. Double Shot Mold(2K mold)6. Unscrewing Molding7. Gas-assisted Molding

8. Die Casting Molding9. Prototype plastic parts and Low cycle plastic parts molding10. Gas Assist molding11. Elastomeric molding12. IML & IMD part production13. Thin wall plastic molding14. High temperature molding