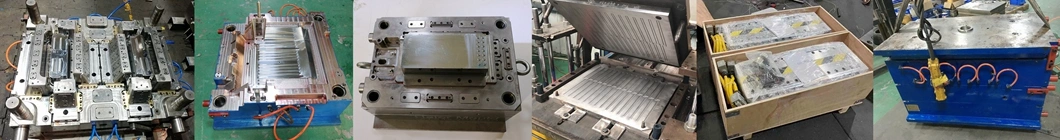

Custom Insert Mold Overmolding Punching Stamping Die Plastic Injection Mold for Auto Parts

Basic Info

| Model NO. | CM01 |

| Plastic Material | PA66+GF |

| Process Combination Type | Single-Process Mode |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE |

| Standard | HASCO |

| Customized | Customized |

| Surface Treatment | Anodizing, Powder Coating ,Paintin etc |

| ODM/OEM | Yes |

| Logo Method | Laser Engraving, CNC Engraving, Screen-Printing E |

| Transport Package | Cartons, Wooden Pallet or Customized |

| Specification | up to design |

| Trademark | Chuangyu |

| Origin | China |

| HS Code | 8480419000 |

| Production Capacity | 5000pieces/Month |

Product Description

Professional Plastic Injection Mould Making and OEM Machining Machinery PartsFor Moulds, pls check the below different grades as to choose the one you want, we will offer the accurate price based on your 3D/2D drawing

| A Grade | B Grade | C Grade | D Grade | |

| Mould Base Standard | HASCO/DME | LKM | LKM | Chinese Local |

| Cavity steel | H13,2344,2343,8407 Heat Hard Steel | 718,738,P20HH, NAK80 | Local P20,WY718 | Aluminum,550C |

| Standard | HASCO,DME | LKM | Chinese Local | / |

| Mould Life | >500K-3000k | 300k-500k | 100k-300k | >10k |

| Runner | Hot runner,cold runner | Hot runner,cold runner | Cold runner | Cold runner |

| Mould Price | Most expensive | Expensive | Cost-effective | Cheap |

Machinery Parts:

| Material | Metal; Aluminum; Brass; Bronze; Copper; Stainless Steel; Plastic; Acrylic; |

| Precision | 0.01-0.05mm or as your request |

| Color | Painting/anodizing/ Polish/silk screen/chromeplate/rubber/coating |

| Surface treatment | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| Transportation | International express by DHL, UPS, etc & by sea |

| Delivery | Within 30~35 workdays after deposit or payment received/ also up to the design |

| Payment terms | T/T, PayPal, West Union,etc |

| Software | Solid work, Pro/E, AutoCAD CAM, Catia |

| QC system | 100% inspection before shipment, product OK rate 99.8% |

| Advantage | Compretitve price,high quality and good after-sales service |

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, Precision EDM, Polishing machine etc. |

| Shipment Terms | 1) 0-500kg: air freight priority |

| 2) >500kg: sea freight priority | |

| 3) As per customized specifications | |

| Packing | 1. Prevent from damage. |

| 2. Foam and paper box or wooden box. | |

| 3. As to customers' requirements, in good condition |

We could make almost all the machining parts according to clients' 2D/3D drawing or samples. Our principle: "Quality to add value, Efficiency to cut costs"

Factory:

We are a very strong and professional factory in mould making and machning parts, we made many moulds for many big company and work with them for so many years, such as Haier, we have our own design team in their company as to design for them special, we pay high attention to the mold's precision as to meet our client's requirement.We also have the professional QC team to check the moulds and machinery parts before shipment as to avoid any mistake.

Our professional and exellent workers:

All of our workers have more than 4 years experience and received professional training from Japanese company as to ensure the products quality.

Certification:

Shipment:

We usually delivery the moulds and machinery parts by sea/DHL/FEDEX/TNT, according to the customers.

FAQ:

1.

Q: what is the processing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well; quote the price to clients after got the 2d or 3d drawings within 2 hours;2.

Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote;

3.

Q: what is the software will you use for the proceeding ?

A: We make the 3D programm with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM etc ;4.

Q: what is the type of machines for manufacturing ?

A: Manufactured from CNC Machining, Laser cutting , stamping ,injection as well as the parts files different ;5.

Q: Do you do the surface treatments please ?

A: Yes, sure. we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting ;6.

Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;

Why choose us?

1. We have more than 10 years experience for production2. We have an extensive expertise in CNC machining, offer "One-stop Service".3. Now we have more than 35 sets of various processing equipment. There are 15 people in professional technology, R&D team.4. All of our operations are strictly compliant with ISO 9001: 2015 guidelines.5. We have office in Germany as to offer better service to our clients.